Passive Component Soldering Profiles

DOWNLOAD PDF

VENKEL'S RECOMMENDED SOLDERING PROFILES

Soldering conditions are affected by mounting and PCB parameters. Please take these factors into account when using these solder profiles. These are recommendations only and no guarantees are implied by them.

COMPONENT TESTING AFTER REFLOW/REWORK FOR MLCC'S:

All component testing after reflow/rework should be performed after ≥ 24hrs to ensure accurate capacitance value measurements. Capacitors should be cooled at room temperature for a minimum of 24 hours to allow the ceramic material to reset (age).

MSL LEVEL

MSL (Moisture Sensitivity Level) is 1

MAXIMUM NUMBER OF REFLOW CYCLES

Maximum Number of Reflow Cycles is 2

RECOMMENDED SOLDERING CONDITION (REFERENCE)

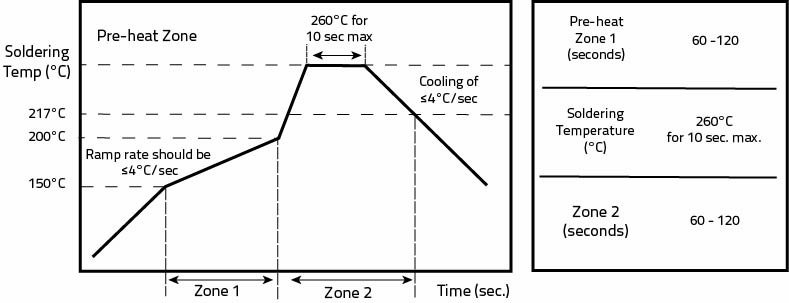

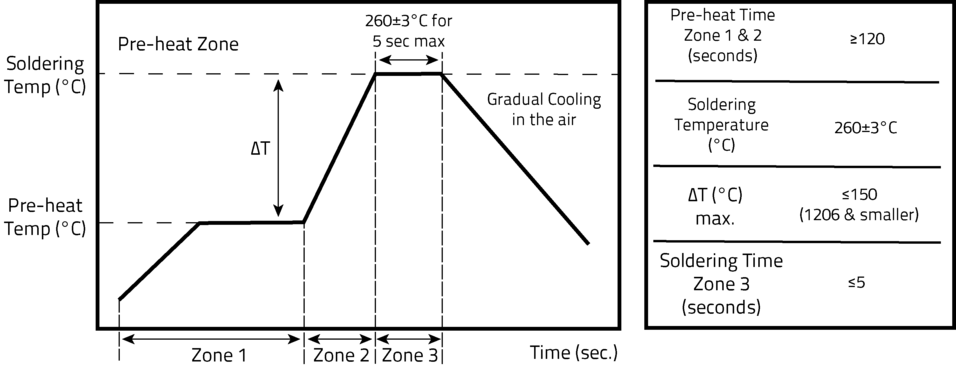

REFLOW SOLDERNG

Recommended condition of Tin(Sn) solder

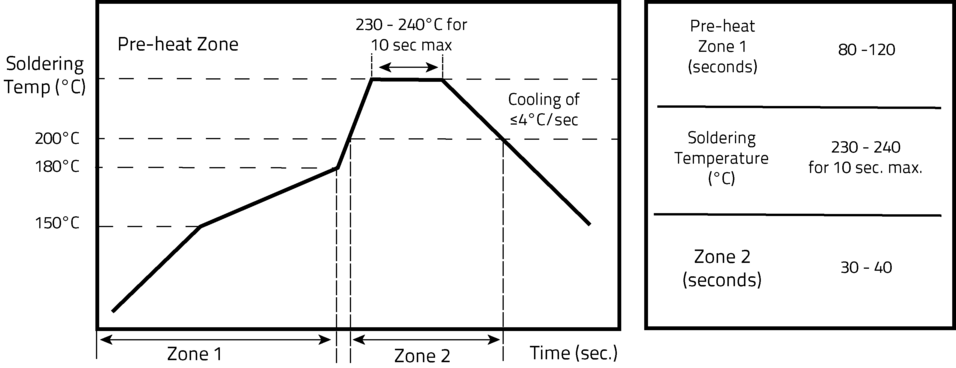

FLOW OR WAVE SOLDERNG

Recommended condition of Tin(Sn) and Tin-Lead (Sn-Pb) solder

Recommended condition of Tin-Lead (Sn-Pb) solder

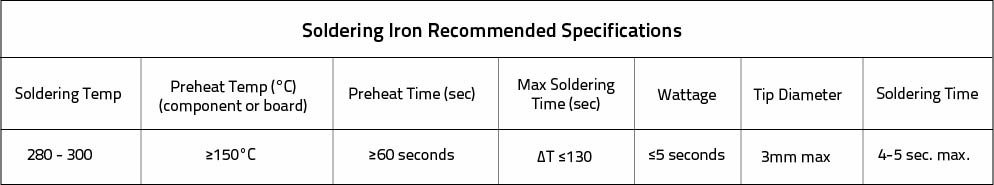

SOLDERING IRON RECOMMENDATIONS (HAND SOLDER)